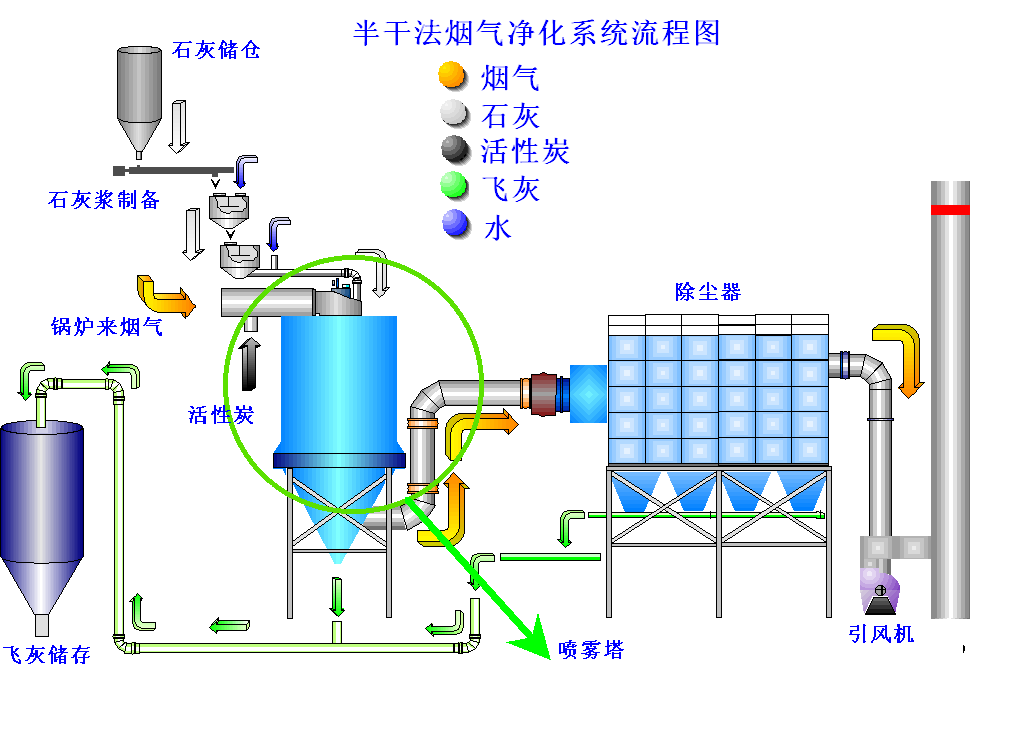

Flue gas purification system

|

Has SNCR\SCR flue gas denitration technology. Curing dry, semi-dry, wet flue gas deacidification technology, bag dust removal, electrostatic dust removal and other flue gas treatment technologies, all emission indicators fully meet the current EU standards, and can be customized for the "near zero emissions" program.

|

|

Flow chart |

|

|

1. Reaction tower

|

|

2, rotary atomizer

|

|

3, atomizing disk

|

|

Reaction tower |

Rotary atomizer |

Atomizing disk |

Atomizing disk |

|

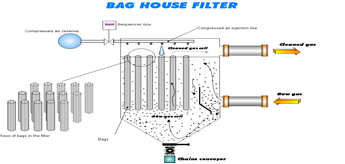

4, dust collector

|

|

|

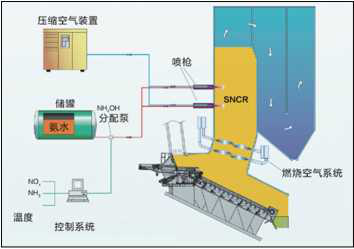

5, SNCR system

|

|

|

Spray gun: good atomization effect, the main body is made of stainless steel 316Ti, the corrosion resistance is very strong, the nozzle adopts high temperature resistance 31Os, the nozzle adopts long tube type design is simple, easy to replace, the front end damage of the nozzle does not affect the spraying effect, the theoretical life is longer, all connections Adopted, convenient.

|

|

6. SCR system: CFD optimization of SCR reactor and flue structure design, effectively reducing flue resistance and saving operating costs. |

|

7, fly ash processing system |

|

8. Emission standards

|

||||||||||||||||||||||||||||||||||||||||||||

|

Note: 1) The standard limits specified in this table are based on the reference value of 11% O2 dry flue gas in the standard state.

|

|

|

|

|

|